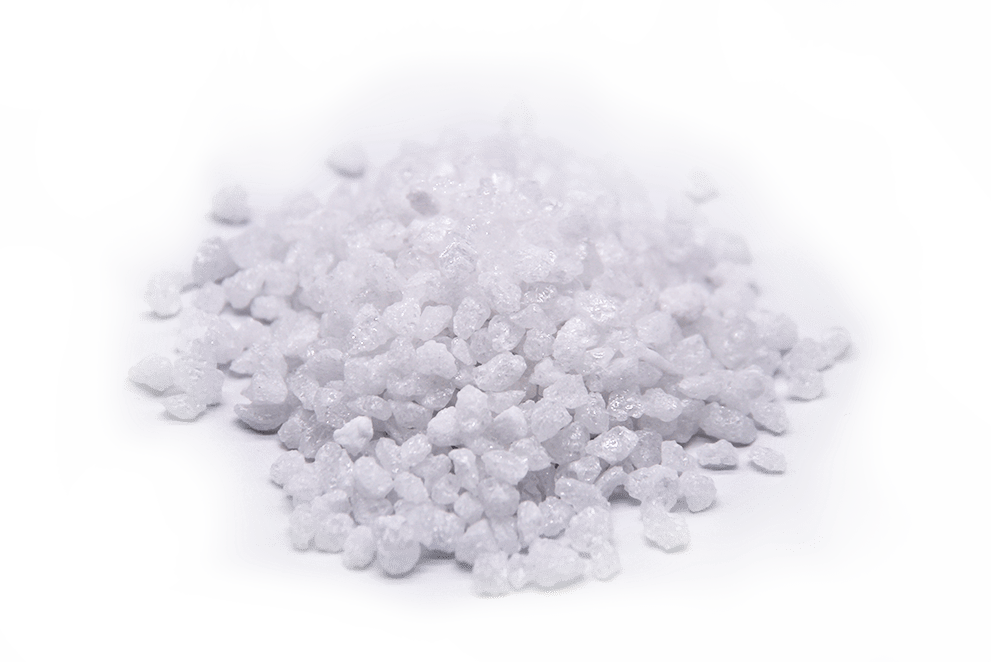

Hasi Na2o Yera Yashizwemo Alumina, Irashobora Gukoreshwa Muburyo bwo Kuvunika, Castable na Abrasives

- Corundum yera

- Alundum yera

- WFA

Ibisobanuro Bigufi

Ibigize imiti

| Ibintu | Igice | Ironderero | Ibisanzwe | ||

| Ibigize imiti | Al2O3 | % | 99.00min | 99.5 | |

| SiO2 | % | 0.20max | 0.08 | ||

| Fe2O3 | % | 0.10max | 0.05 | ||

| Na2O | % | 0.40max | 0.27 | ||

| Kwanga | ℃ | 1850min | |||

| Ubucucike bwinshi | g / cm3 | 3.50min | |||

| Mohs gukomera | --- | 9.00min | |||

| Icyiciro gikuru cya kristaline | --- | α-Al2O3 | |||

| Ingano ya Crystal: | μm | 600-1400 | |||

| Ubucucike nyabwo | 3.90min | ||||

| Gukomera | Kg / mm2 | ||||

| Impamyabumenyi | Ingano | mm | 0-50,0-1, 1-3, 3-5,5-8 | ||

| Mesh | -8 + 16, -16 + 30, -30 + 60, -60 + 90 | ||||

| Amande | mesh | -100, -200, -325 | |||

| Abrasive & Blasting Grade | FEPA | F12-F220 | |||

| Kuringaniza & Gusya Urwego | FEPA | F240-F1200 | |||

Ibara ryera rya Alumina

| Ibicuruzwa / Ubwoko | Al2O3 | SiO2 | Fe2O3 | Na2O |

| WFA Intete za Soda Ntoya n'amande | > 99.2 | <0.2 | <0.1 | <0.2 |

| WFA 98 Ibinyampeke n'amande | > 98 | <0.2 | <0.2 | <0.5 |

| WFA98% Amande Yaciwe -200, -325 na -500Mesh | > 98 | <0.3 | <0.5 | <0.8 |

| Ibintu | Ingano | Ibigize imiti (%) | |

| Fe2O3 (min) | Na2O (max) | ||

| WA & WA-P | F4 ~ F80 P12 ~ P80 | 99.10 | 0.35 |

| F90 ~ F150 P100 ~ P150 | 98.10 | 0.4 | |

| F180 ~ F220 P180 ~ P220 | 98.60 | 0.50 | |

| F230 ~ F800 P240 ~ P800 | 98.30 | 0.60 | |

| F1000 ~ F1200 P1000 ~ P1200 | 98.10 | 0.7 | |

| P1500 ~ P2500 | 97.50 | 0.90 | |

| WA-B | F4 ~ F80 | 99.00 | 0.50 |

| F90 ~ F150 | 99.00 | 0.60 | |

| F180 ~ F220 | 98.50 | 0.60 | |

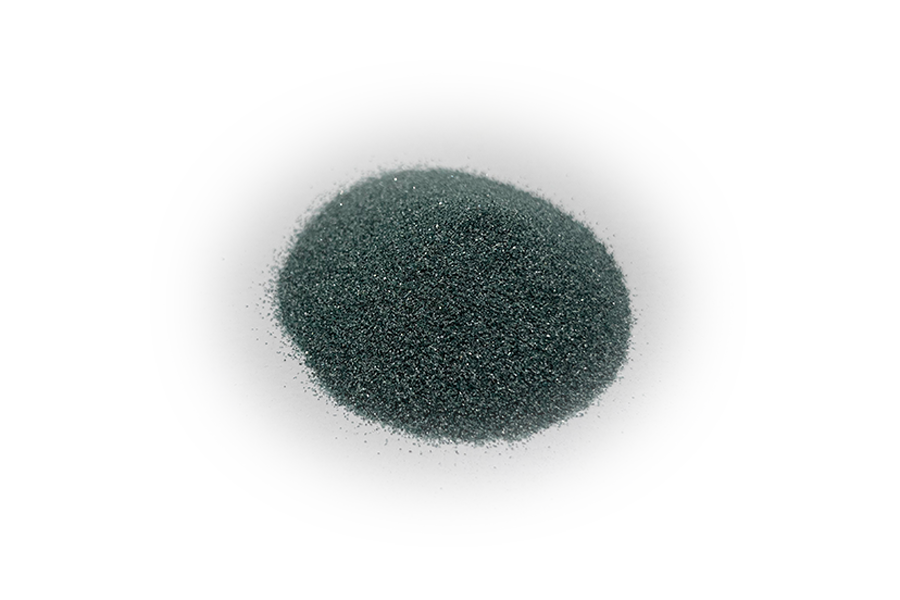

Ibikoresho bito nuburyo bwo gutanga umusaruro

Umweru Fused Alumina ni isuku ryinshi, imyunyu ngugu.

Yakozwe no guhuza urwego rwiza rwiza Bayer Alumina mu itanura ryamashanyarazi yubushyuhe burenze 2000˚C hakurikiraho inzira yo gukomera buhoro.

Kugenzura cyane ubuziranenge bwibikoresho fatizo nibipimo bya fusion byemeza ibicuruzwa byera cyane kandi byera cyane.

Igikonje gikonje cyongeye kumenagurwa, kwozwa umwanda wa magneti mumashanyarazi menshi atandukanya kandi agashyirwa mubice bigufi kugirango bikoreshe impera.

Gusaba

Imirongo yihariye itanga ibicuruzwa kubikorwa bitandukanye.

Umweru Fused Alumina urashobora gukarurwa cyane bityo ukaba ukoreshwa mubicuruzwa bya Vitrified Bonded Abrasives aho ibikorwa byiza, gukata byihuse nibyingenzi ndetse no mugukora inganda zuzuye za Alumina.Izindi porogaramu zirimo gukoresha muri Coated Abrasives, Kuvura Ubuso, Amabati ya Ceramic, Amabara yo Kurwanya Skid, Amashyiga yo kuryama ya Fluidized hamwe nuruhu / Kuvura amenyo.

Ibyerekeye Umusaruro